ROI and Payback Period of the NIA Platform

In many factories, production losses happen every day, but they aren’t seen clearly, consistently, or fast enough to act on. Unplanned machine stops, running below standard speed, and repeated defects often get buried in manual logs and end-of-shift summaries. When data arrives late (or not at all), decisions are delayed, improvements become inconsistent, and the same problems keep returning.

These problems can be improved with the NIA Platform, a real-time OEE monitoring system that works together with the MC TRACK device.

MC TRACK is a device that tracks machine operating status, covering productive time (Good Time), unplanned downtime (Downtime Loss), cycle time per unit (Cycle Time), and the number of units produced. All data is sent to the NIA Platform to be processed and displayed in an easy-to-understand format.

This allows the factory to check production status in real time against standard criteria, and helps production teams, maintenance teams, and management use the same set of data to monitor performance, identify the causes of losses, and drive machine efficiency improvements using real data.

Where ROI from an OEE Monitoring System Comes From

ROI (Return on Investment) from an OEE monitoring system comes from reducing hidden costs and increasing valuable production time, through four main mechanisms:

1) Improve Machine Availability

Real-time visibility highlights repeated stoppages and time-loss patterns. Teams can prioritize the biggest downtime drivers, fix recurring issues, and reduce unplanned interruptions.

2) Improve Performance

Speed losses become visible when actual cycle time is compared to the defined standard. This helps operators and engineers bring machines closer to their true capacity and more consistently.

3) Improve Quality

Defects and rework can be linked to specific times, jobs, or machine conditions, making it easier to find the root cause and prevent the same issue from happening again.

4) Build a Trusted Data System for Faster Decisions

By reducing reliance on manual reporting, every department works with the same accurate dataset. Daily meetings become faster and more effective because decisions are based on real production data.

ROI and Payback Period: Calculation Method

Use the following simple formulas to estimate returns:

- Annual Gross Benefit (THB/year)

= Additional Units per Year × Incremental Profit per Unit - Net Annual Benefit (THB/year)

= Annual Gross Benefit − Annual Operating Cost - Simple Annual ROI (%)

= (Net Annual Benefit ÷ One-Time Investment) × 100 - Payback Period (months)

= One-Time Investment ÷ (Net Annual Benefit ÷ 12)

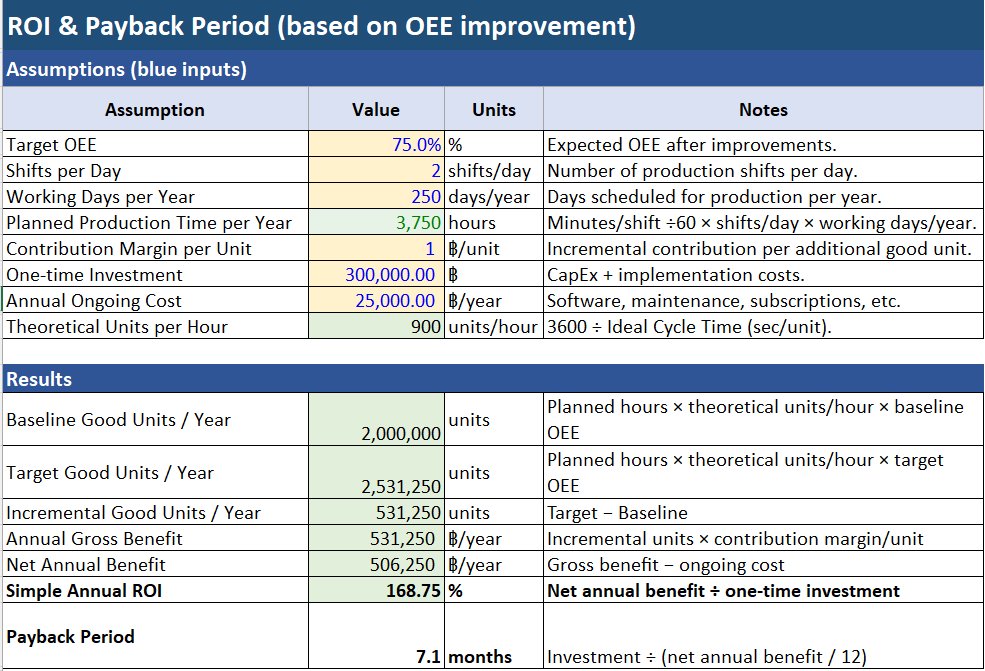

Sample ROI Calculation

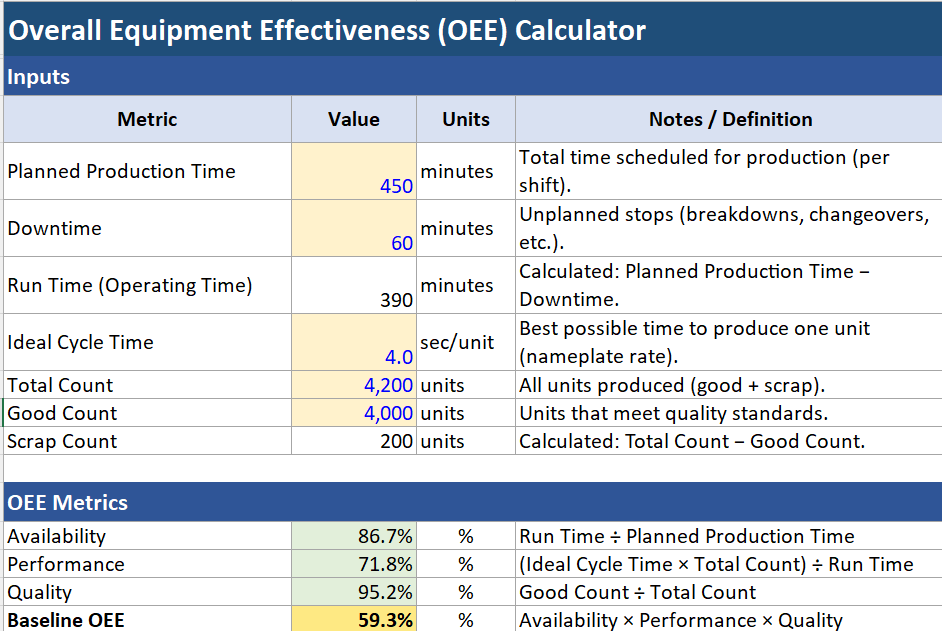

To illustrate, here’s an example based on our OEE Calculator (values can be adjusted to match your factory):

Key assumptions

- OEE (before): 59.3%

- OEE (after installing NIA Platform): 75%

ROI & Payback result

Using the formula:

ROI (%) = (Annual Gross Benefit − Annual Operating Cost) ÷ Initial Investment × 100

ROI (%) = (531,250 – 25,000) ÷ 300,000 × 100

ROI ≈ 168.75% per year

Payback Period ≈ 7.1 months

How to Achieve Real ROI After Installation

To get real ROI, we recommend these three practical steps:

1) Set Data Standards

Define machine states, standard cycle time, and real downtime reasons that production teams can use consistently.

2) Focus on the Top Losses

Identify the top 3 loss drivers, assign a person in charge, and set clear targets.

3) Run Continuous Improvement Cycles (PDCA)

Review results weekly/monthly using the same dataset. Track impact, validate improvements, and prevent the same issues from returning.

Toyota Tsusho NEXTY Electronics (Thailand) developed the NIA Platform, a real-time OEE monitoring solution designed to help Thai manufacturers modernize performance management.

By making production losses visible before they accumulate into major costs—including unplanned downtime, speed loss, and recurring defects—factories can reduce time and cost losses while improving customer confidence through results that are measurable and transparent.

Summary

A strong OEE monitoring system should help a factory see losses faster and convert that visibility into improvements you can measure.

With NIA Platform, operations are guided by real-time data, enabling teams to reduce wasted time, increase valuable production time, and monitor ROI using ongoing performance data.

TH

TH EN

EN