Unleashing the Power of OEE: The Key for Success Every Industry Needs!

Have you ever wondered why some factories achieve outstanding productivity and high profits, while others struggle with delays, rising costs, and frequent machine downtime?

The secret is knowing your Overall Equipment Effectiveness, or OEE, which tells you how efficiently your factory is running. It's the key to setting your business apart from the competition!

Why OEE Matters for Your Business?

Imagine that every second your machine is down, you're losing money! And if you can't control and identify the causes of these losses, it leads to higher costs and missed business opportunities. OEE helps you clearly understand what is preventing your machines from performing at their best. It highlights every problem area and gives you the opportunity to improve your production processes, driving continuous progress!

Understanding OEE

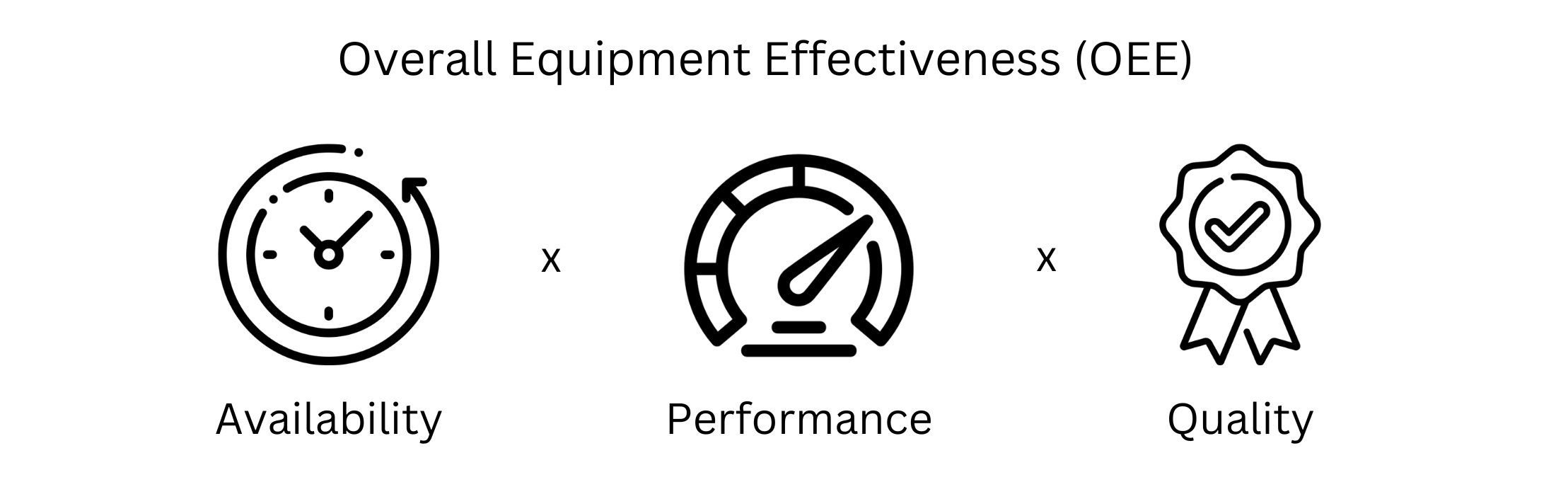

OEE is made up of three key components:

1. Availability – Measures how much time your machine is either down or operating below its optimal performance level.

2. Performance – Compares the actual speed at which your machine is running to its ideal operating speed.

3. Quality – Measures the proportion of good-quality products produced compared to defective ones.

Together, these elements give you a full picture of how efficiently your machines are operating.

How OEE is calculated

Example Calculation:

Availability = Actual operating time ÷ Planned operating time

Example: Machine operates for 7 hours out of an 8-hour shift.

Availability = (7 ÷ 8) × 100 = 87.5%

Performance = Actual production rate ÷ Maximum production rate

Example: Machine produces 420 pieces/hour, while the maximum capacity is 500 pieces/hour.

Performance = (420 ÷ 500) × 100 = 84%

Quality = Number of good products ÷ Total products produced Example: 400 pieces produced, with 10 defective pieces.

Quality = ((400 - 10) ÷ 400) × 100 = 97.5%

OEE = Availability × Performance × Quality

= 87.5% × 84% × 97.5% = 71.6%

What Is Your OEE Level?

1. 85% or higher: World-class factory

2. 60–85%: Good performance, but room for improvement

3. Below 60%: Critical issues—immediate analysis and action required

6 Big Losses That Affect OEE

1. Downtime – Unplanned machine stoppages

2. Setup and Adjustment – Time lost during machine setup

3. Small Stops – Short, unnecessary stoppages

4. Reduced Speed – Machines running slower than expected

5. Defects – Production of defective products

6. Startup Rejects – Defects occurring during machine startup

How to Improve Your OEE?

1. Track Real-Time Data

IoT technologies like MC Track and AI can monitor and analyze machine data in real time, allowing you to detect issues early and respond immediately.

2. Preventive Maintenance

Preventive maintenance reduces downtime and increases machine availability. By regularly checking and maintaining machines—such as changing lubricants and inspecting worn parts—you can avoid unexpected failures. IoT data also enables predictive maintenance before problems arise.

3. Staff Training

Skilled teams can dramatically improve production efficiency. Investing in staff training on machine operation and maintenance ensures problems are solved quickly and effectively.

Conclusion

Understanding OEE not only helps you measure machine performance but also provides insights for long-term business growth.

Want to learn more? Contact us now and take your production to the next level.

TH

TH EN

EN